Awarded with Focus Open 2022 Meta Award | our smart city district

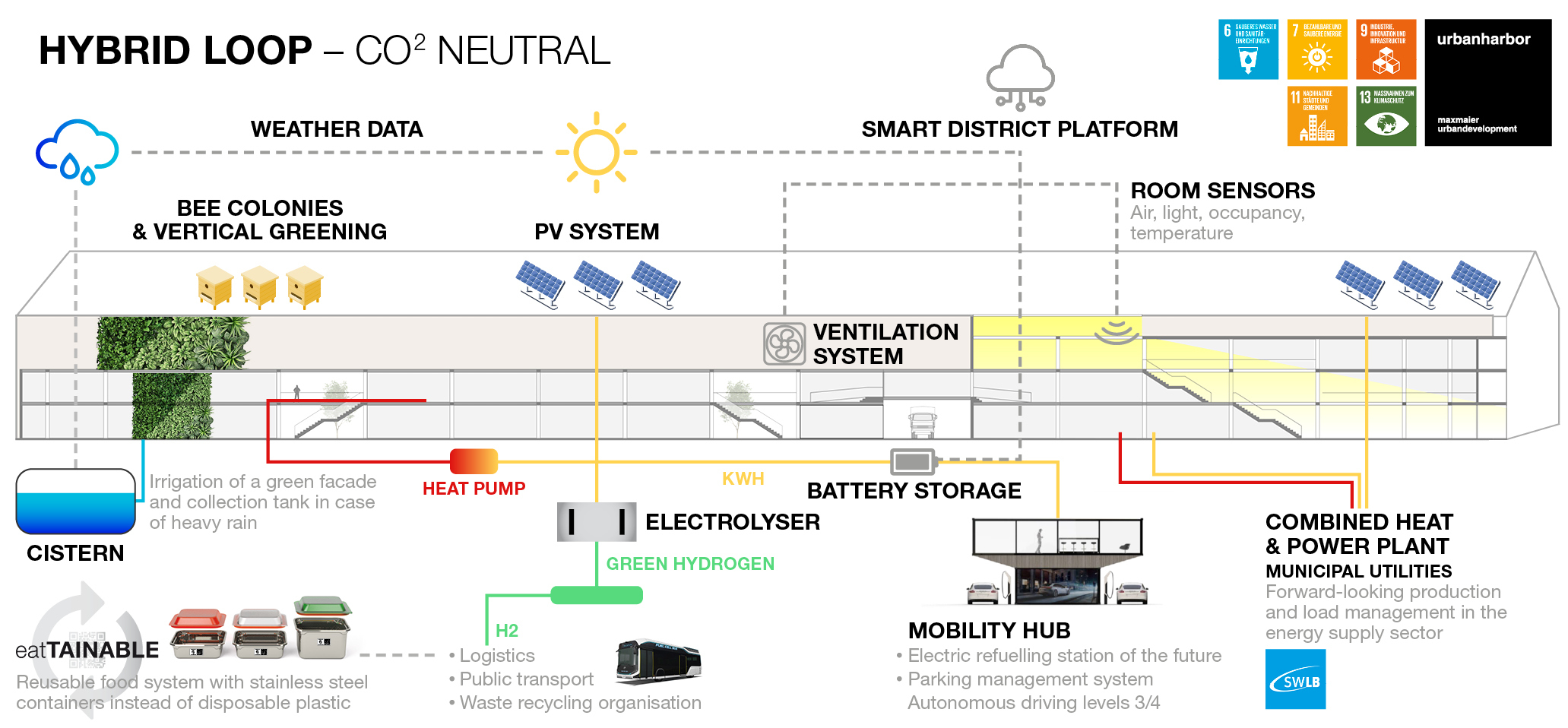

Collaboration smart city district platform – CO2 neutral @urbanharbor

we capture more CO2 in our real-estate than we emit

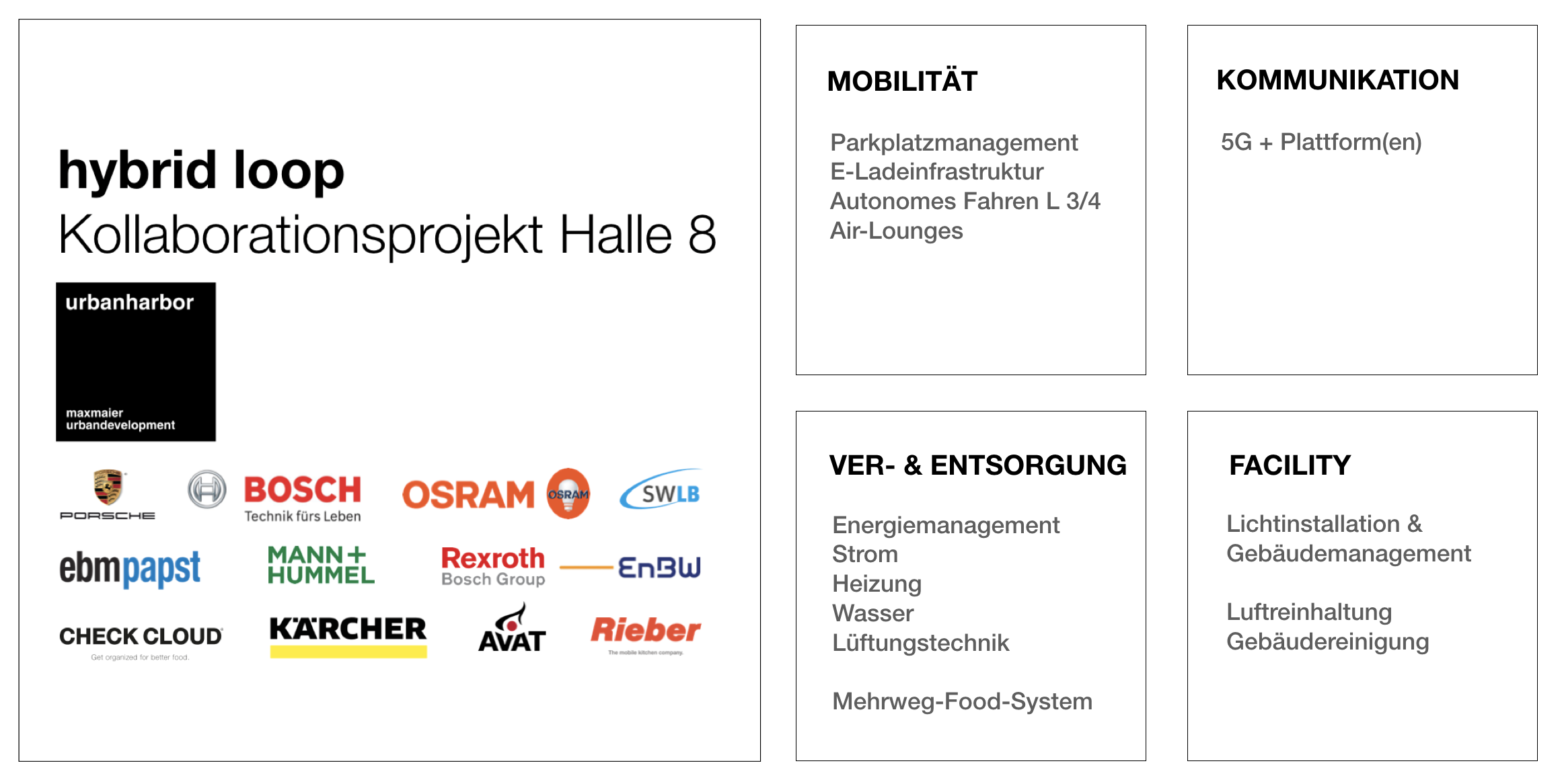

Through the collaboration of companies from various sectors and activities, their sustainable and digital solutions are to be networked via a joint platform in order to create a holistic organisational tool for a city ecosystem. All processes will be organised and automatically controlled with maximum efficiency and minimum use of resources. This is because neighbourhoods are in competition with end customers (tenants), and important decision-making criteria include costs, benefits and use of resources.

© Thunert Fotograf

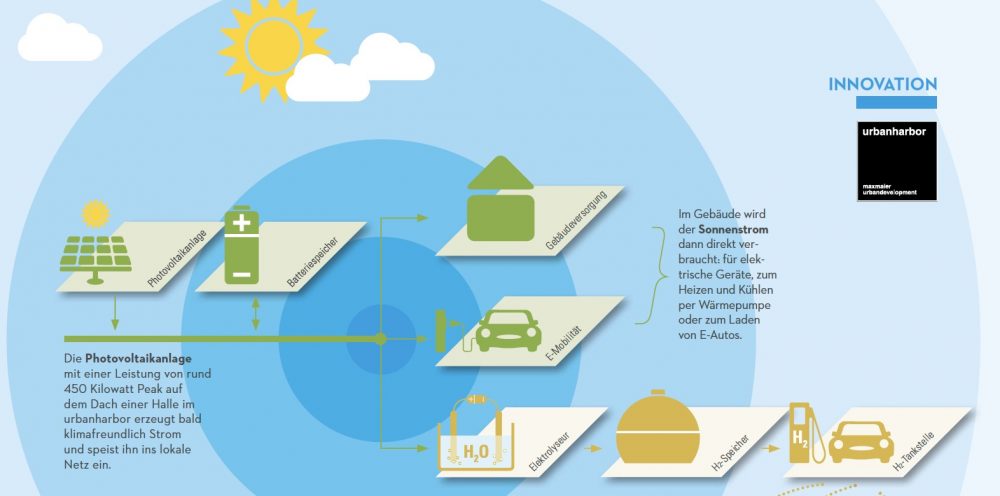

Supply & disposal concepts – zero emission

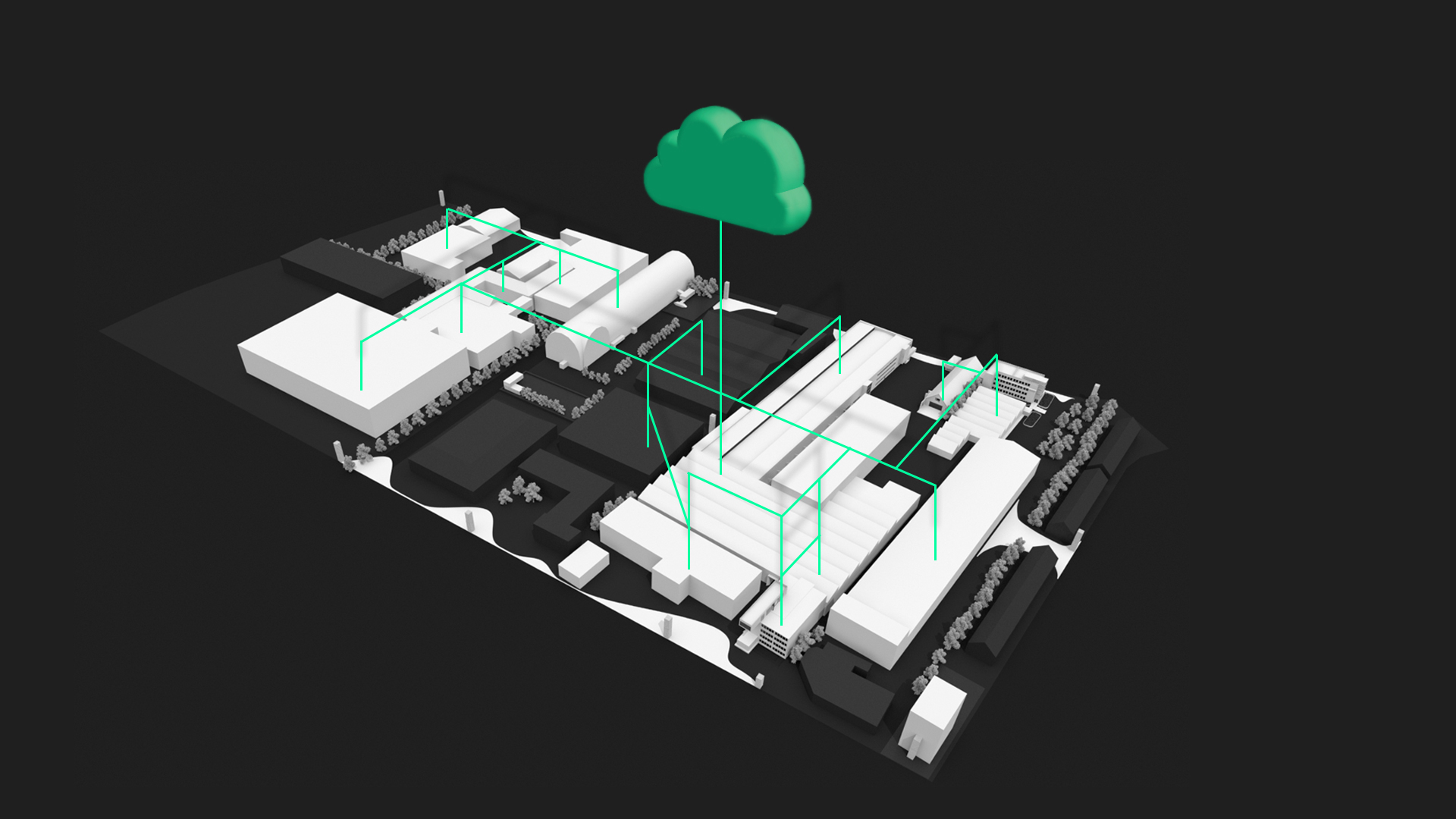

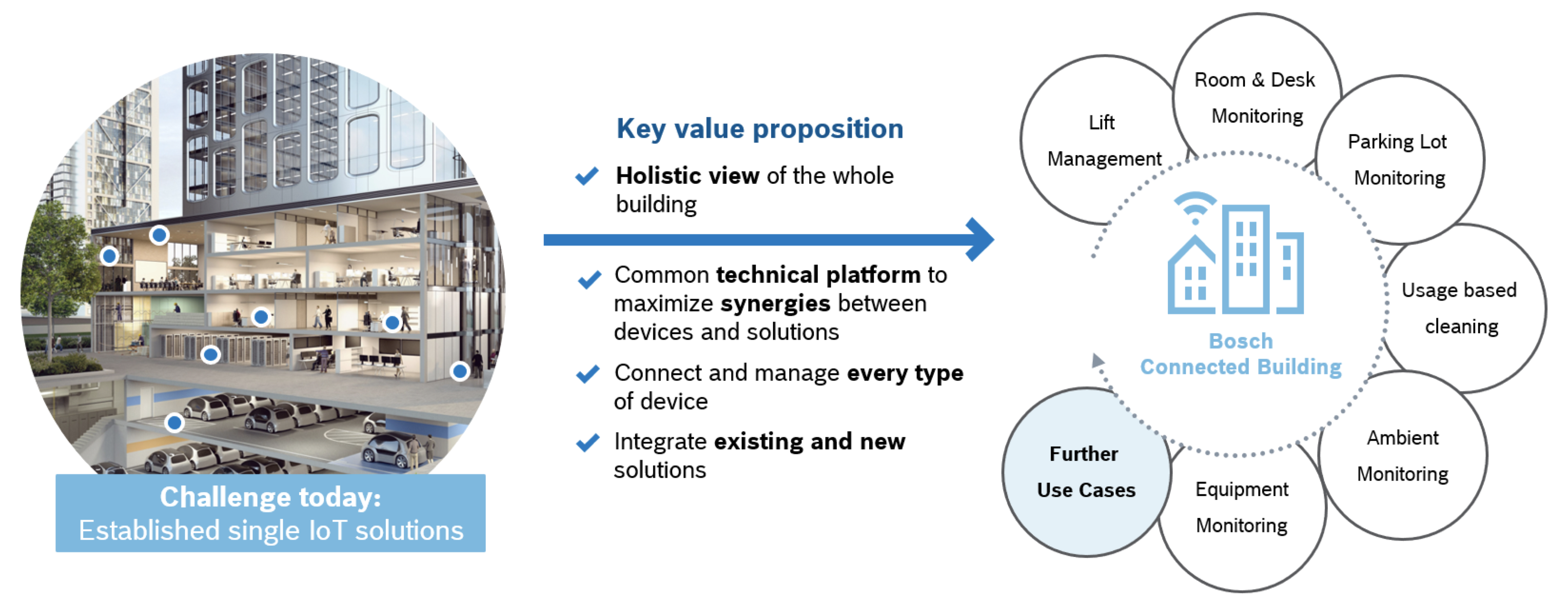

In the transformation of the industrial hall into an IoT-future factory, data is collected and correlated in real time via a platform, from supply and disposal to mobility and facility management, and these systems are consequently controlled and optimised as required.

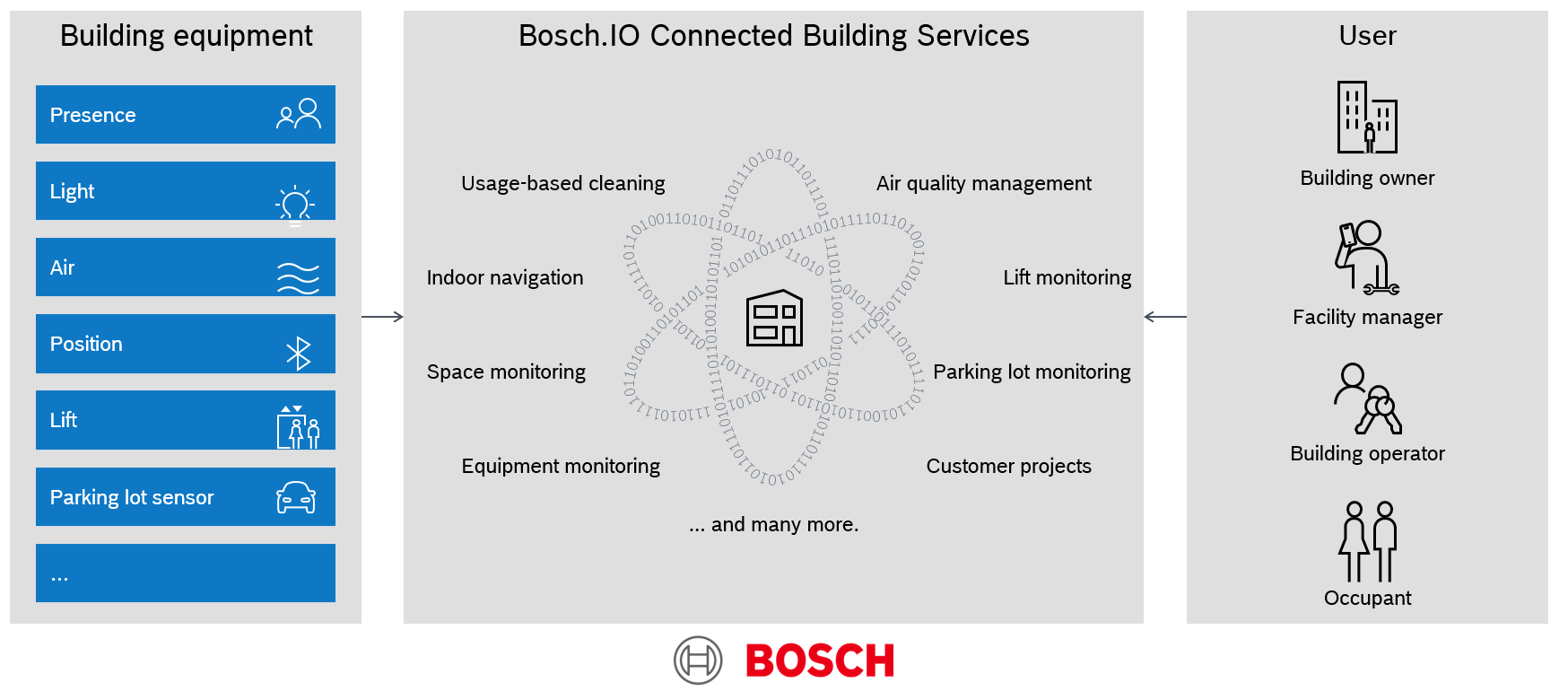

Bosch.IO provides the connecting piece by means of the building platform. It networks the devices and building infrastructure, brings the data into a uniform format and creates a digital image of the building to evaluate its current and historical condition. In this way, building operators, owners and users can easily use the data and further develop the optimisation of building use on its basis.

For energy management, a neighbourhood concept is being designed together with the Ludwigsburg public utility company, which should be scalable and transferable to other neighbourhoods.

The basic idea is to network the individual systems, such as the ventilation system, lighting, heating and component activation of the building, on the basis of room occupancy (real-time occupancy plans), room temperatures (inside and outside), air quality (CO2, VOC…), so that ongoing operation can be carried out with the minimum use of resources. The current consumption values and forecasts of future consumption are provided by Bosch.IO.

Translated with www.DeepL.com/Translator (free version)

Facility management – zero emission

In addition to the classic facility management areas, the project focuses increasingly on the sustainable optimisation of the working climate for the employees themselves. The fundamental well-being of the employees is a key criterion, with the objective of maximum efficiency and added value of the MA, while at the same time achieving the highest level of employee satisfaction – especially in the IT sector, a WAR FOR TALENTS is taking place.

Important criteria that contribute to employee satisfaction and are therefore taken into account in the area concept are the accessibility of the workplace (routes, parking spaces incl. charging infrastructure, bicycle stands, P+R, public transport, etc.), as well as the quality of the workplace itself, through the design for an innovative and natural environment.

Furthermore, the influence of temperature, air quality, light and safety on physical well-being is optimally controlled. The various building media are covered by Kärcher (for needs-based hygiene and cleaning management), MANN+HUMMEL (for air purification and filtration) and Osram (for lighting control systems).

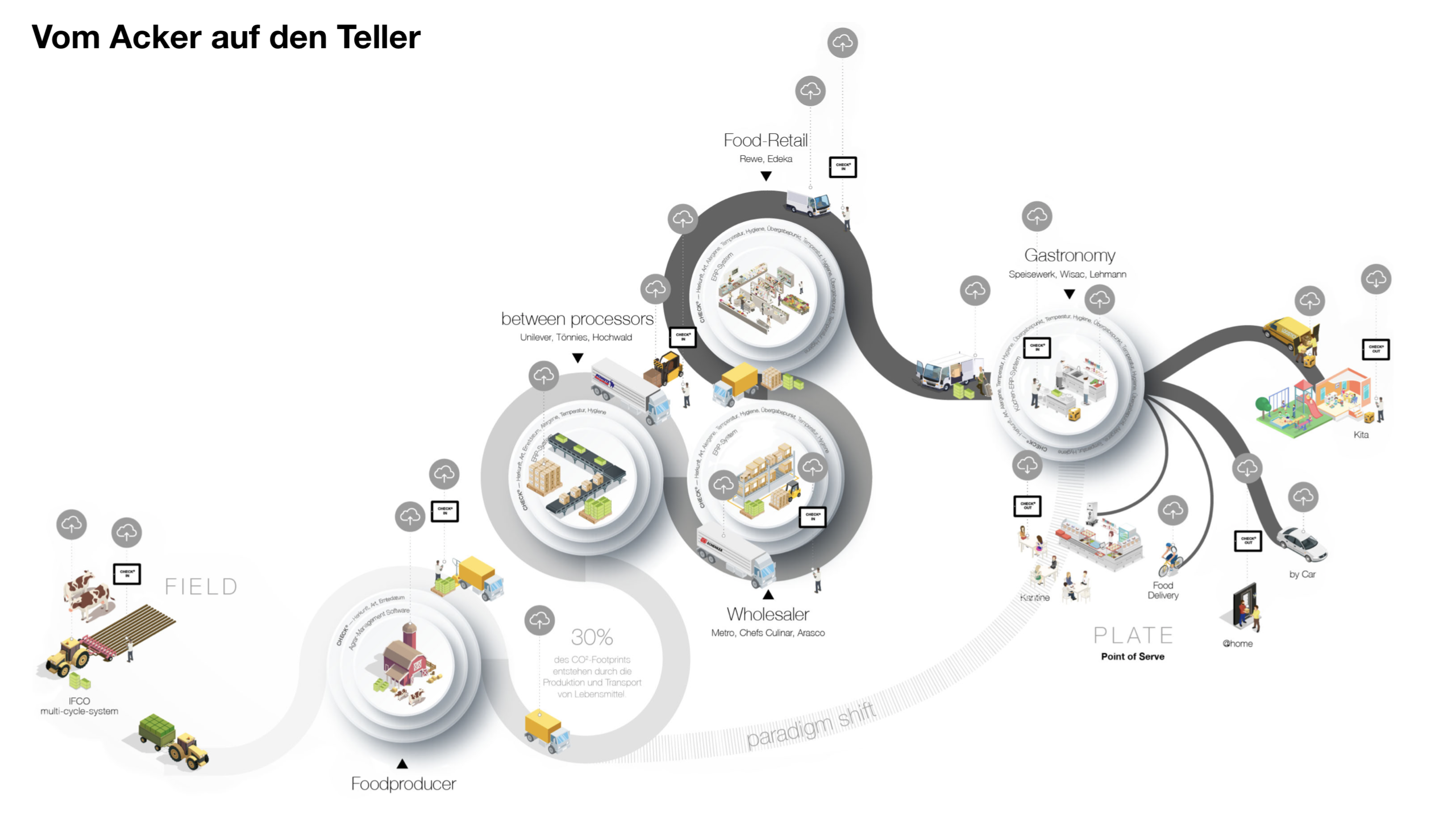

CHECK CLOUD digital food safety

The quality of food is a function of the correct temperature and time throughout the entire food process. With CHECK HACCP, these quality-relevant factors can not only be documented in a digitally transparent way, but workloads can be facilitated and processes optimised. The CHECK CLOUD is an open, manufacturer-independent platform for different service partners with individual expertise. This collaboration creates a variety of solutions to enable fresh food from the field to the plate without waste and economic pressure.

The future of the food supply chain

The CHECK CLOUD links the quality-relevant information from all sequences of the food supply chain – such as storage, processing, production, transport, trade and delivery models. This enables food producers, wholesalers and retailers, restaurateurs as well as manufacturers of machines and equipment used along the value chain to make decisions about quality assurance and to counteract existing weaknesses at an early stage. In addition to the various process participants, private consumers and legal authorities also benefit for the first time from the comprehensive transparency, which on the one hand saves costs and time, but above all leads to more trust.

Process transparency and organisation is the solution to eliminate food waste and its packaging – through an intelligent system with standards. The goal is to increase the value of the food with every person involved in the process, from the origin to the recipes, the ingredients and allergens – digitally documented via upstream processing stages and in the long term up to the guest himself.

Mobility concepts – zero emission

Together with Porsche, modular mobility container lounges will be set up on the urbanharbor campus by March 2020. The aim is to offer a wide range of mobility options – e-vehicles, e-bikes or e-scooters – with an integrated e-charging infrastructure, powered by solar energy and CHP storage, and efficiently utilised through sharing pool concepts.

In the lounge area, the user is also offered services related to the vehicle (cleaning/repairs) and on the other hand a lounge area as a co-working space, innovative reusable food concepts, also to-go, up to integrated retail areas for direct sales and other bookable service offers – all digitally communicated and organised.

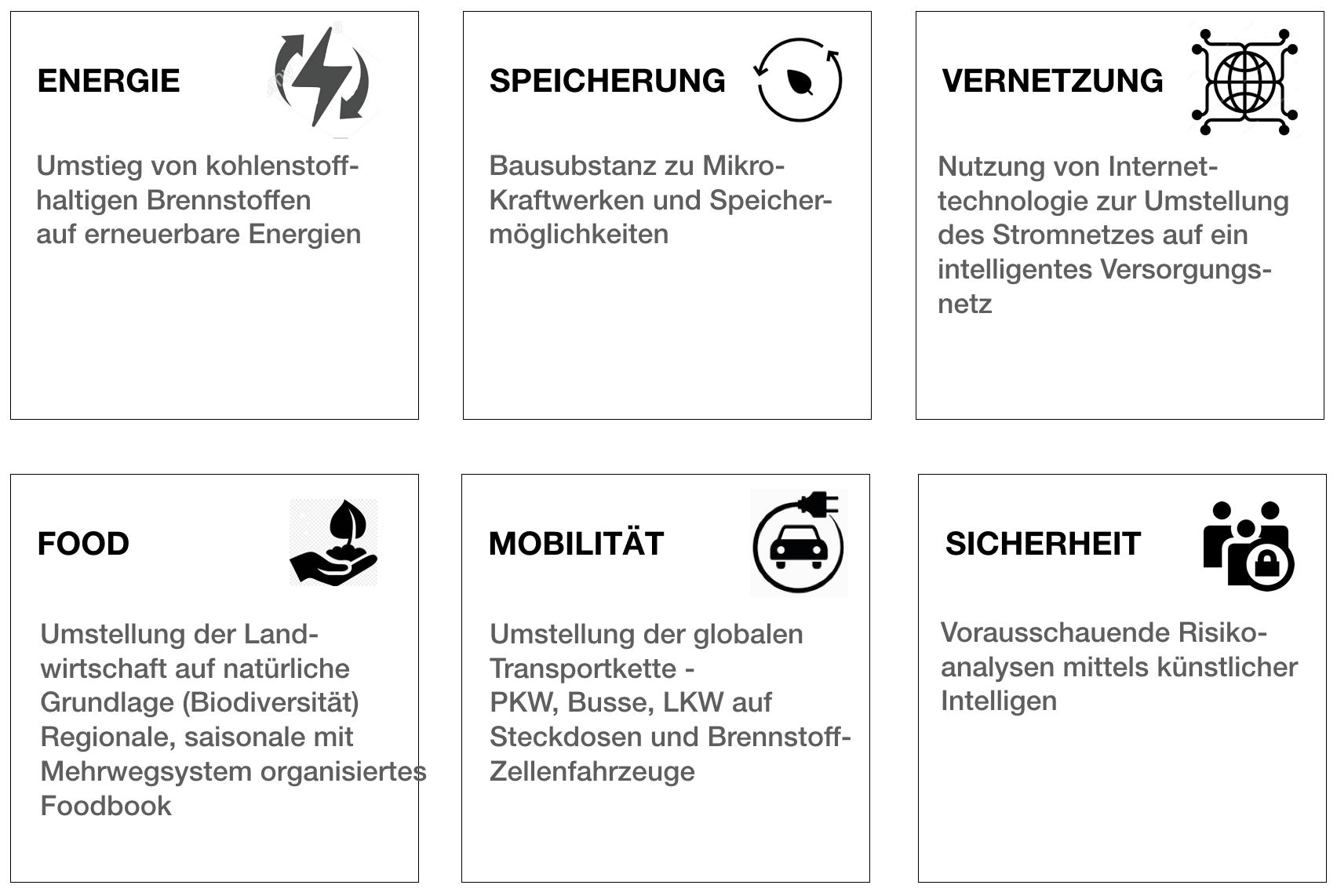

Sector coupling

All energy-relevant sectors are linked on the „mm-data-engine“.

- Energy industry/generation (CHP, solar, geothermal)

Industry 4.0 (robotics) - Mobility (e-mobility, fast charging stations, parking management)

- Agriculture and new food concepts (regionality, reusable system instead of single-use plastic, zero food waste)

- Food safety with the use of the digitalisation platform CHECK

- Real estate industry (real estate as power plant and storage for all sectors)

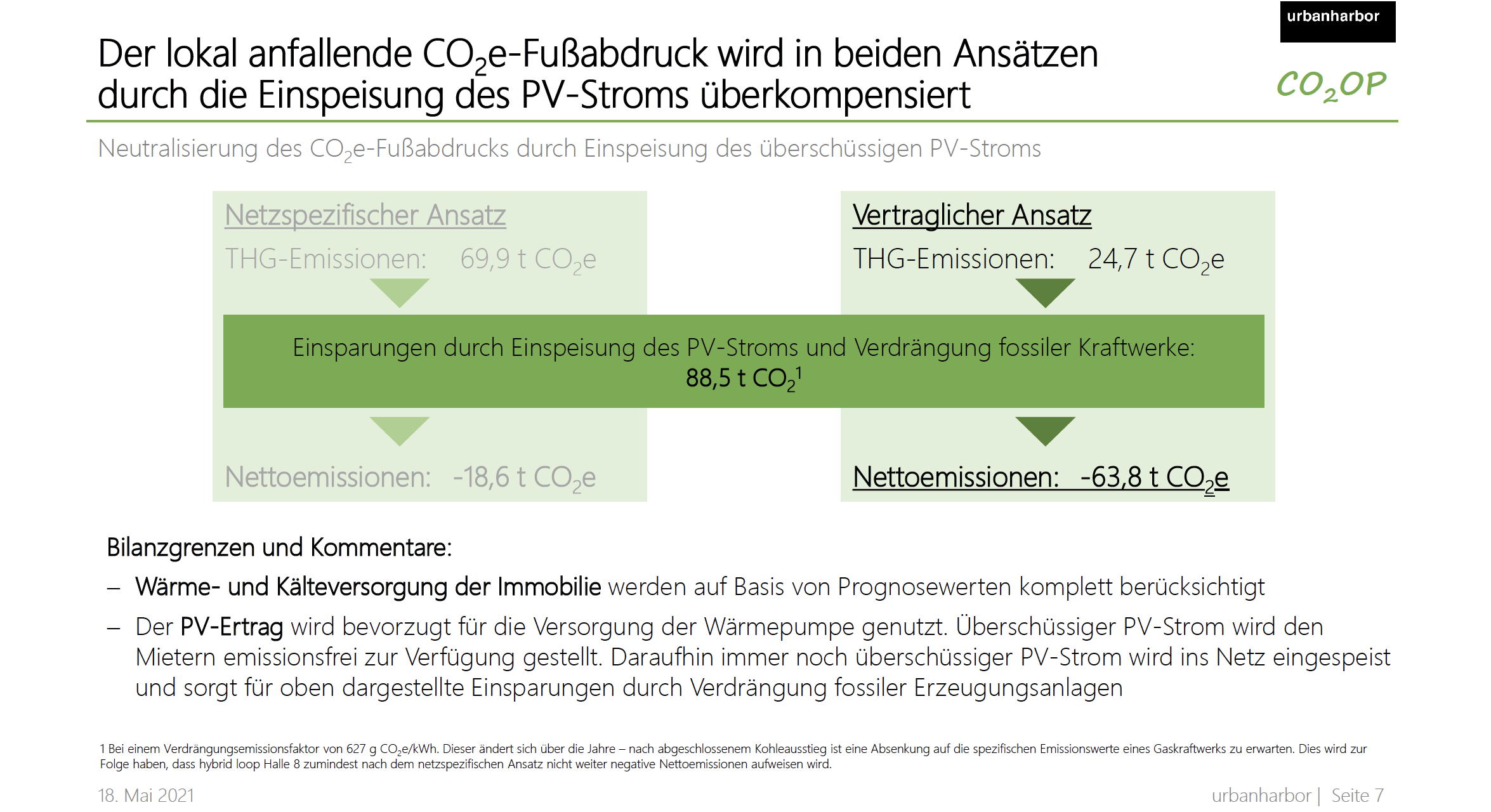

we capture more CO2 in our real-estate than we emit

Savings from surplus PV electricity (hybrid loop | recorded biliancially for a building)

you have to plant 5040 trees to compansate 63 t CO2 e / year

In order to be able to absorb one tonne of CO2, the beech must grow for about 80 years. This means that beech trees absorb 12.5 kilograms of CO2 per year. So you would have to plant 80 trees to offset one tonne of CO2 by trees every year.